Electrostatic Air Filters

At Typhoon Roasters, we prioritize sustainability and environmental responsibility. Our advanced air filters are specifically designed to optimize your coffee roasting process while minimizing emissions and ensuring compliance with environmental standards

-

Suitable for

10kg – 30kg Roasters

Tech specifications

- 2.5kg

- 5kg

- 10kg

- 20kg

- 30kg

- Cabinet size (L*W*H) 1240*765*690 mm

- Power 110W (W/O UV) / 190W (W/ UV)

Superior Filtration for Sustainable Coffee Roasting

- Superior Filtration for Sustainable Coffee Roasting

- High-Efficiency Filtration: Captures 99.5% of fine particles and roasting emissions.

- Sustainable Design: Reduces environmental impact without compromising performance.

- Easy Maintenance: Designed for simple cleaning and long-lasting durability.

- Versatile Fit: Compatible with various roaster sizes and customizable to your setup.

Experience cleaner air and sustainable coffee roasting with Typhoon Air Filters – built for excellence and the future of eco-friendly roasting

What our clients say about Typhoon Roasters

8 Reasons to Switch

to Convection Right Now

Convection roasters maintain consistent performance, regardless of external conditions like ambient temperature or humidity. Instead of pulling in room air, they circulate and reheat internal airflow to create a stable roasting environment. A built-in thermal insulation layer shields the machine from environmental fluctuations, ensuring steady results throughout the day.

Unlike conduction roasters, convection systems don’t build up excess heat over time, so there’s no need to constantly adjust your roasting profiles during long production runs

Convection roasters make it easy to replicate roast profiles, both manually and automatically. They respond instantly to input changes without delays from metal inertia, giving you precise control throughout the process. With energy transferred directly to the beans, you get stable heat and minimal variation at the most critical points of the roast

Convection roasting eliminates common defects caused by overheated metal surfaces. Unlike traditional systems, the stainless steel components in Typhoon roasters don’t retain excess heat and cool down quickly. An active layer of hot air separates the beans from direct metal contact, reducing the risk of scorching and ensuring an even, consistent roast every time

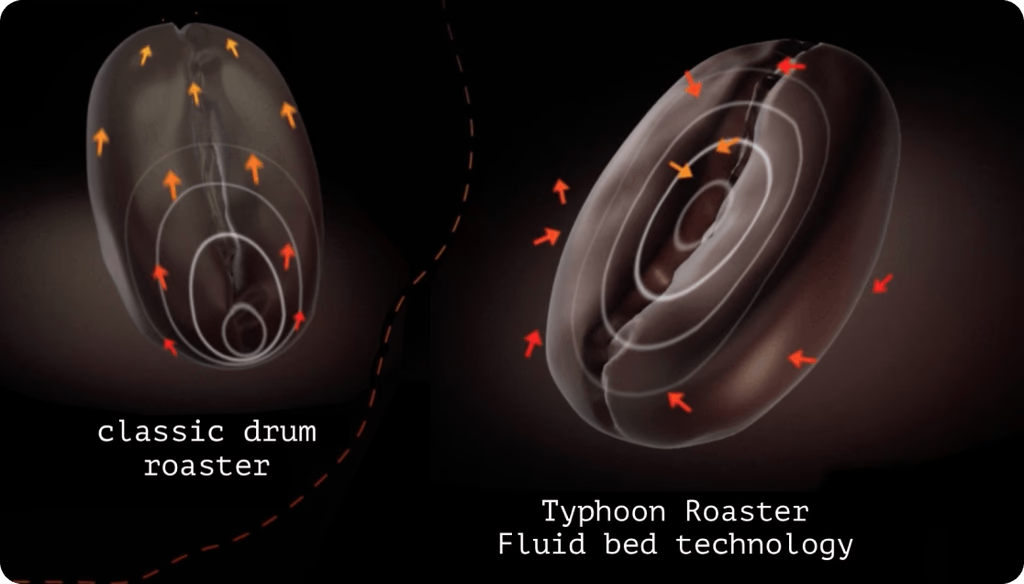

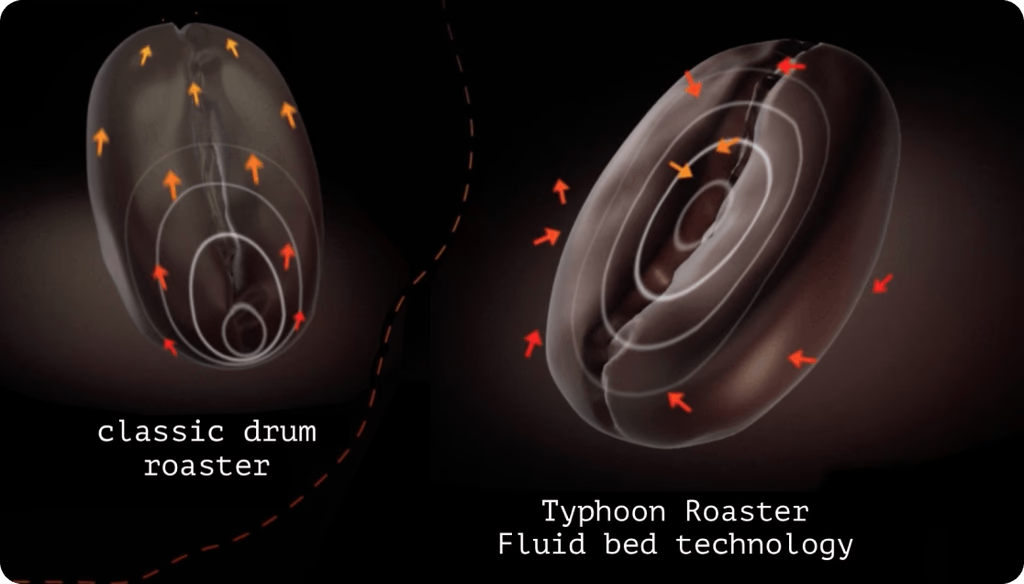

Fluid bed technology in convection roasters delivers consistently even results by distributing the beans across a horizontal surface and moving them with controlled airflow. This design prevents prolonged contact with hot metal surfaces, unlike traditional drum roasters that rely on mechanical paddles. The result is a uniform roast with reduced risk of scorching or uneven development

Convection roasting offers clear advantages for espresso, especially with medium to dark roasts. It produces a dense, full-bodied cup with enhanced sweetness by gently caramelizing the coffee’s natural sugars. Thanks to consistent heat distribution, convection roasters ensure the uniformity that’s essential for the short, intense extraction process of espresso brewing

Convection roasting brings out the natural sweetness and clarity of light roasts, especially in naturally processed beans. The result is a clean, fruity cup with well-defined flavor notes. Even heat distribution and the absence of roasting defects allow the coffee’s true character to shine through

Convection roasters bring out the best in fine commercial coffee by gently caramelizing sugars and highlighting natural sweetness. They reduce the risk of defects and prevent over-roasting, resulting in consistently even roasts with rich, smooth flavor — especially ideal for medium to dark profiles

Convection roasters can process up to 6 batches per hour, nearly double the output of traditional conduction roasters. With average roast cycles of just 6 to 8 minutes, they operate 30 to 40 percent faster. Because heat is evenly applied across the entire surface of each bean, and no downtime is needed between batches, you can load to full capacity without sacrificing quality

Get Expert Help Choosing Your Perfect Roaster