Quick Summary

- A roasting schedule that falters during peak hours is usually a planning issue rather than a problem with the roaster itself; demand, capacity, and communication are simply out of sync.

- You can stabilize production by mapping demand by day and channel, separating production days from R&D, maintaining a small roasted coffee buffer for weekends and peak periods, and calculating realistic “roaster hours per week” based on your machine’s effective batch size and batches per hour

- Most commercial roasters perform optimally at 70–90 percent of their nominal batch size and around 3–4 batches per hour, depending on roast time and cooling. As a result, actual hourly output is typically lower than the nameplate specification.

- Simple inventory and scheduling tools allow you to track green and roasted stock, orders, and planned batches in one place, enabling you to roast precisely what is needed instead of constantly firefighting.

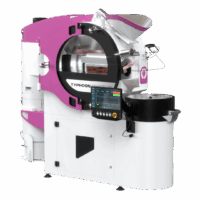

- High-productivity roasters with fast cycles and no cooldown between batches, such as Typhoon’s electric convection roasters (up to 6 batches per hour, 15–30 kg/h depending on the model), make it easier to consolidate production into fewer days and maintain a healthy buffer without constant supervision at the roaster.

Designing a roasting schedule that survives peak hours

Many roasteries run smoothly on quiet Tuesdays but struggle on Fridays. Wholesale orders arrive late, the café runs out of espresso, you end up roasting late into the night, and everyone promises, “Next week we’ll plan better.”

Managing peak hours is less about heroic roasting and more about designing a schedule that treats your roaster as a production tool rather than a magical black box.

This guide provides a practical framework to help.

- 2–3 planning models,

- a simple way to calculate “roaster load per hour”,

- and a few communication tricks so you stop fighting fires with your baristas and wholesale customers.

1. Map your real demand

Before adjusting the schedule, you need to understand exactly what you are scheduling.

Answer three questions:

- Where does your demand come from?

- Espresso bar in your own café

- Retail bags

- Wholesale (regular vs occasional)

- Online orders

- When does demand spike?

Many roasteries experience higher order volumes mid-week and before weekends or holidays. Track several weeks of orders and café usage to identify patterns instead of relying on guesswork. - How much stock are you comfortable holding?

- For espresso blends, many cafés are happy with 3–7 days of roasted stock.

- For delicate filter roasts, you may aim for 2–4 days to keep them fresh.

Record it by SKU: “Espresso House Blend — average 12 kg/week, weekend peak 18 kg, target buffer 3 days.”

This information forms the backbone of your schedule.

2. Choose a scheduling model

There is no single “correct” schedule. Most small roasteries gravitate toward one of these three models (or a mix).

Model A: Dedicated production days

You roast on 1–3 fixed days per week, then pack and ship on the others.

Good for:

- Roasteries with regular wholesale

- Teams that want clear “production days” vs “office days”

How it works:

- Monday & Thursday: full production days

- Tuesday: packing + shipping

- Wednesday: lighter production + R&D

- Friday: buffer and last-minute top-ups

You size each production day to cover demand until the next one, plus a small buffer.

Model B: Rolling “roast to order” with a buffer

You roast smaller batches more frequently, staying close to orders.

Good for:

- Smaller cafés and roasteries

- Very fresh-forward brands with many SKUs

How it works:

- Daily cut-off time for orders (e.g. 11:00)

- Roast in the afternoon for next-day dispatch

- Maintain a 1–2 day buffer for core blends, almost zero buffer for rare single origins

This approach allows flexibility, but it is essential to protect roaster time; otherwise, every late order turns into an emergency.

Model C: Hybrid with R&D days

You split your week into:

- Production days for core blends and wholesale

- Flex/R&D days for new coffees, dial-ins and training

For example:

- Mon, Wed, Thu — production

- Tue — light production + R&D

- Fri — top-ups, sample roasting, cupping

This often represents the sweet spot for growing roasteries: production is safeguarded, yet there is still room for innovation.

3. Calculate “roaster hours”

To know whether your schedule survives peak hours, you need one simple number:

Roaster hours needed per week

Here is a straightforward way to approximate it:

- Find your effective batch size

Most roasters work best at 70–90 percent of nominal capacity. A “6 kg” machine, for example, may run more consistently at 5–5.5 kg per batch. - Estimate batches per hour

If your average roast + cooling cycle is 12–16 minutes, you can expect about 3–4 batches per hour, including loading and unloading. Data for commercial machines in the 5–60 kg class shows this as a typical range. - Calculate hourly output

Hourly kg = effective batch size × batches per hour

Example: 5.5 kg × 3.5 batches ≈ 19 kg/h. - Divide your weekly volume

Roaster hours per week = total weekly kg / hourly kg

If you need 150 kg per week and your hourly output is ~19 kg, you need about 8 hours of roasting time. Add:

- 10–20% more for warm-up, cleaning, mistakes

- Extra time if you run many different SKUs and profiles

Now incorporate this into your planning model. If you only have one 4-hour roasting slot per week but calculations show you need 10, it does not mean you are “bad at time management”, your schedule is simply unrealistic.

4. Build a buffer for weekends and peaks

Even the best schedule will fail if it is based solely on the average day and ignores demand spikes.

Use your demand map to define:

- Base demand — what you need on a “normal” day

- Peak demand — what happens before weekends, paydays, or subscription shipments

- Buffer — how many extra days of roasted stock you want for each key SKU

Practical tips:

- Build your weekend buffer earlier in the week, such as Wednesday or Thursday, rather than on Friday evening.

- For each core blend, define minimum and maximum roasted stock. For example, “never less than 1 day, never more than 5 days on the shelf.”

- Use simple inventory tools or spreadsheets to track roasted and green stock, pending orders, and scheduled batches in a single view. Software like RoastLog, Beanventory, or dedicated roastery templates can automate this process and alert you when stock is running low.

The goal is not to build huge stock, but to maintain a small, reliable buffer that protects you from a single large wholesale order depleting your café’s espresso supply.

5. Communicate so you don’t fight fires every week

A well-designed schedule can fail quickly if it is not respected by those around you.

Establish a few simple rules and communicate them clearly to baristas and wholesale customers:

- Order cut-off times

For example, “Orders for Wed/Thu dispatch must be in by 12:00 the previous day.” - Clear lead times for large orders

“Anything above 30 kg of a single SKU needs 3 business days.” - Substitutions and backups

Decide in advance what happens if a specific coffee runs out: can you replace it with another profile, or is it “wait until next roast day”? - One person owns the schedule

Someone in the roastery, even if it is you, must be responsible for deciding whether a request can be accommodated immediately or will need to be fulfilled on the next production day.

When your team knows the constraints, last-minute “fires” drop dramatically.

6. How this looks on high-productivity systems (Typhoon example)

With more productive roasters, your schedule can be more compact without compromising buffer or freshness.

Consider a mid-size roastery that requires approximately 150 kg per week across blends and single origins.

On a typical 5–6 kg drum roaster with ~5.5 kg effective batches and 3–4 batches per hour, you might achieve around 18–22 kg per hour. This translates to 7–9 roaster hours per week, often distributed over several days.

Now compare that to an electric convection roaster like the Typhoon 5 PRO:

- Up to 30 kg/h of roasted coffee

- Up to 6 batches per hour with no cooldown between cycles

- Roast times of about 6–7 minutes per batch

The same 150 kg can be roasted in roughly 5 roaster hours, often within a single focused production day, leaving the rest of the week for:

- Packing and shipping

- R&D and new coffees

- Maintenance and cleaning

- Actual breathing room for the team

Smaller setups see a similar effect: a Typhoon 2.5 PRO can deliver 15 kg/h at 6–7 minute cycles, effectively matching the hourly output of a typical 5 kg drum roaster while using less energy per kilogram.

The point is not that you must use a specific machine. Rather, when your roaster can run more batches per hour without cooldown, your schedule becomes more flexible. You can choose to roast small amounts frequently or consolidate production into one or two days while still staying ahead of peak demand.

7. Putting it all together

A roasting schedule that withstands peak hours is built, not improvised:

- Map your demand by day, channel, and SKU.

- Choose a planning model, whether production days, rolling, or a hybrid approach.

- Calculate realistic roaster hours based on actual machine performance.

- Maintain a modest buffer for weekends and demand spikes.

- Communicate cut-offs and lead times to ensure the schedule is respected.

- Use equipment and tools that support your plan rather than working against it.

Whether you roast on a classic drum or an electric convection roaster, this framework allows you to design a week where peaks are predictable, enabling your team to focus on roasting excellent coffee instead of managing operational emergencies.